Top Muskegon Remodelers

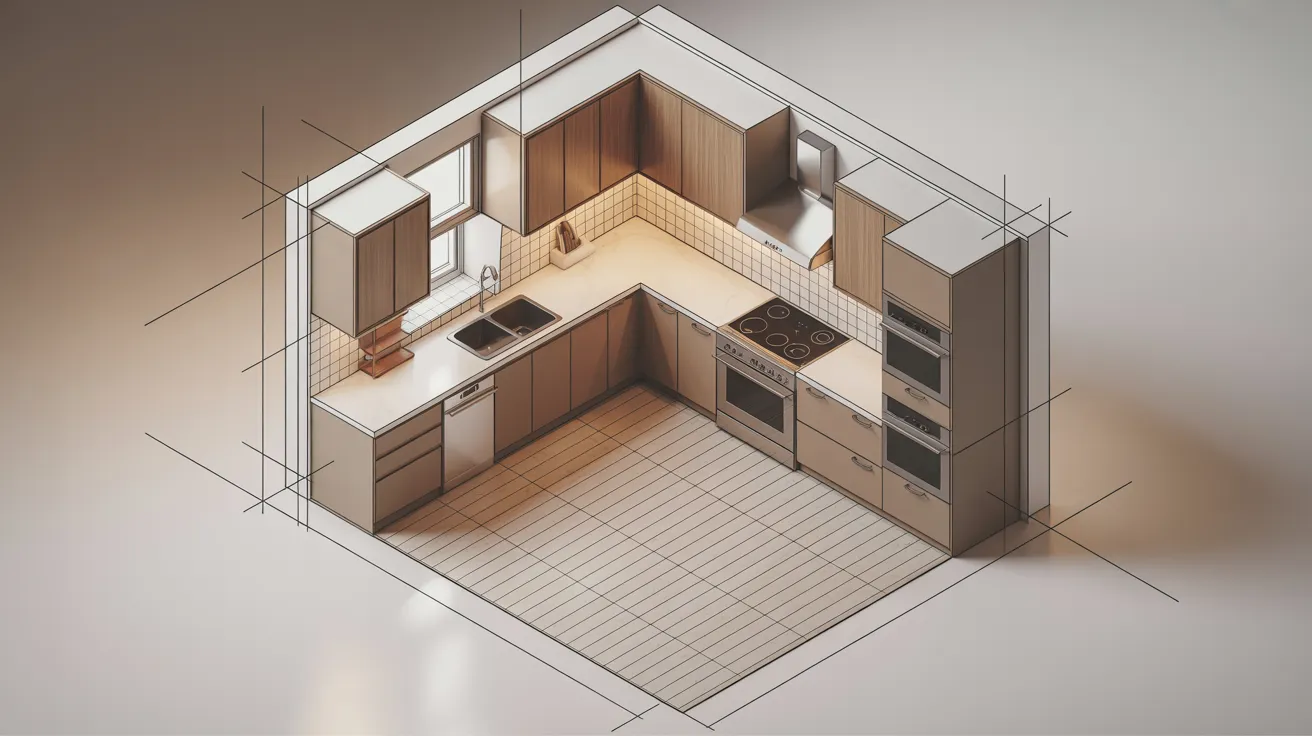

You need a Muskegon remodeler who is familiar with Michigan Residential Code, schedules inspections and utility shutoffs around lakeshore seasons, and validates lead times before demo. We provide measurements, space planning, and deliver permit-ready MEP drawings, then create with kiln-dried hardwood cabinets, Grade 1 hardware, quartz tops, ANSI A108 tile, and NEC/GFCI/AFCI compliance with proper ventilation CFM and makeup air. Expect line-item pricing, a critical-path schedule, and weekly updates with documented options for variances. Discover how this approach preserves your budget, timeline, and project performance.

Main Points

- Certified Muskegon design-build team providing permit-ready plans, precise budgets, and clear schedules with regular weekly progress updates.

- Extensive expertise in Michigan Residential Code, inspections, GFCI/AFCI, ventilation CFM, and tempered glazing near ranges.

- Organized procurement with local suppliers to confirm lead times before demolition, reducing downtime and change orders.

- Craftsmanship-first materials: kiln-dried hardwood cabinetry, Grade 1 hardware, quartz countertops, ANSI A108 tile assemblies, and moisture-resistant substrates.

- Seasonal preparation for lakeshore climate: hardwood adaptation, winter cure times, makeup air systems and vent terminations designed for durability during freeze-thaw cycles.

Exactly Why Regional Expertise Is Essential in Muskegon Kitchen Remodeling Projects

From permits through product delivery timelines, local expertise ensures your Muskegon kitchen remodel on budget, compliant, and efficient. You benefit from contractors who know municipal plan review cycles, inspection sequencing, and current Michigan Residential Code requirements for electrical load calculations, GFCI/AFCI protection, ventilation CFM, and tempered glazing near ranges. Regional familiarity streamlines trade coordination, identifies reliable suppliers, and anticipates utility shutoff windows.

You'll sidestep project holdups as a local pro checks lead times on cabinets, panel upgrades, and solid-surface fabrication before demolition. Seasonal considerations matter on the lakeshore: humidity alters hardwood acclimation, winter temps impact curing times, and freeze-thaw cycles affect exterior vent terminations and make-up air compliance. Local teams schedule rough-ins around weather, protect finishes in transit, and keep clear permit documentation to complete inspections efficiently.

Design-Build Process: From Your Vision to the Finished Product

Regional knowledge only offers worth when it's arranged through a defined, accountable design-build system. We begin with discovery: assess current conditions, confirm utilities, and record code requirements. Then we develop space planning that optimizes work zones, circulation, and clearances per IRC and local amendments. You assess schematic choices and a draft budget connected to quantities.

Subsequently, we develop permit-ready drawings: schematics, elevations, MEP layouts, and specifications coordinated with energy and ventilation requirements. During preconstruction, we complete scope, schedule, and contractor coordination, organizing trades to minimize downtime and secure your home.

Building proceeds according to a documented schedule, with site safety protocols, daily logs, and progress inspections at key phases. You receive transparent change management and punch-list resolution. Final delivery encompasses as-builts, warranties, and post-occupancy check-ins.

Quality Materials and Expert Craftsmanship Built to Last for Generations

Although design defines intent, durability stems from disciplined material selection and verified workmanship. You receive long-life performance when every component fulfills spec and every connection is executed to standard. We source kiln-dried Solid hardwood for cabinet frames and doors, assembled with dovetail or mortise-and-tenon construction to resist racking. Hinges and slides are ANSI/BHMA Grade 1 for cycle durability. For work surfaces, Quartz countertops offer nonporous hygiene, high compressive strength, and consistent slab coloration.

We specify moisture-resistant substrates adjacent to sinks, sealed end-grain, and stainless fasteners to avoid corrosion. Tile assemblies comply with ANSI A108 including crack isolation when required. Backsplash and penetrations receive silicone rated for food zones. Electrical boxes, GFCI protection, and appliance clearances are compliant with NEC. Venting, makeup air, and finishes meet manufacturer requirements to preserve warranties.

Budgeting, Project Timelines, and Honest Communication

Founded upon that same rigor, your project plan synchronizes scope, budget, and schedule with the identical specificity we apply to materials and code. We initiate cost planning that details labor, fixtures, finishes, permits, and contingencies, so you view line-by-line effects before approvals. You'll receive a baseline schedule with critical path activities, inspection milestones, and lead times for custom components.

We copyright a predictable communication schedule: each week's progress summaries, change-order confirmations within 24 hours, and same-day notice if a issue affects timeline or budget. Variances trigger documented options—de-scope, substitution, or resequencing—each with price and timeline deltas. You approve before we continue. Permit compliance and inspections are timed to avoid idle days. The result: controlled costs, reliable timelines, and no surprises.

Portfolio Highlights and What Homeowners Are Saying

Frequently the strongest proof click here is the work itself: our portfolio encompasses full-gut kitchen remodels, ADA-compliant layouts, historic bungalow restorations, and high-performance upgrades that adhere to Michigan Residential Code and Energy Code. You'll see clear scope definitions, stamped permits, and inspected milestones shown through Before after photos, finish schedules, and appliance specs.

We demonstrate cabinet box construction, soft-close hardware ratings, and ventilation sizing that satisfies M1503. Range clearances, GFCI/AFCI protection, and tamper-resistant receptacles conform to electrical code. Our air sealing, R-values, and LED efficacy satisfy Energy Code standards without reducing aesthetics.

Client feedback confirms the metrics. Property owners mention dust control, schedule adherence, and punch-list closure. You'll find clean reveals, straight quartz seams, and proper toe-kick recesses. Inspect our warranty terms and service logs to assess performance after move-in.

Common Inquiries

Are Permits and Inspections Handled by the Remodeling Team or Homeowners?

Typically, the remodeling team takes care of permits and inspections, but you hold final oversight. We establish permit responsibility in the contract, develop code-compliant drawings, submit applications, and coordinate AHJ approvals. We handle inspection scheduling, meet inspectors on-site, and address correction notices promptly. You authorize fees and provide property access. If you prefer DIY permitting, we'll furnish documentation and guidance. Our goal: zero surprises, clear accountability, and a compliant project from demo to final.

Do You Provide Accessibility and Aging-In-Place Kitchen Modifications?

Indeed-we craft kitchens that evolve elegantly with you. Visualize moving along an unobstructed route: mobility-friendly arrangements, extended corridors, lever-operated fittings, and skid-proof flooring guide every step. We incorporate reduced-height countertops, slide-out storage, D-shaped handles, and side-opening ovens for safe access parameters. Lighting focuses on tasks; switches and sockets achieve ADA-inspired heights. We define reinforced walls for upcoming safety bars and zero-threshold passages. You obtain standard-meeting blueprints, detailed measurements, and harmonized inspections, start to finish.

What Warranties Cover Labor and Installed Appliances or Fixtures?

You receive a 2-year Labor warranty on installation per contract, transferable, and compliant with local codes. Appliance coverage follows manufacturer warranties (typically 1-2 years parts/labor), with our confirmed startup and registration to initiate extended protections when available. Installed fixtures come with manufacturer warranties; we honor labor for warrantable defects within our term. Not covered: misuse, owner-supplied items, and consumables. We supply warranty documentation, serials, and claim support, ensuring prompt, code-compliant remediation.

How Do You Manage Unanticipated Structural Issues Discovered During Demolition?

You manage unexpected structural issues by stabilizing immediately and planning swiftly. With 37% of remodels exposing hidden defects, you implement temporary shoring, document any hidden joist damage, and perform load-path calculations. You secure circuits, cap unexpected plumbing, and schedule inspections to ensure code compliance. You initiate contingency budgeting, issue a written change order, and sequence repairs to limit downtime. You validate moisture content, use approved connectors, and pass rough-in inspections before proceeding with finishes.

Are You Able to Work With Third-Party Interior Designers or Appliance Suppliers?

Indeed. You undertake designer collaboration from concept through punch list, providing CAD files, finish schedules, and shop drawings for exact integration. You also oversee supplier coordination, validating specifications, lead times, rough-in requirements, and delivery windows. You confirm UL/ETL listings, ADA clearances, ventilation CFM, and electrical/gas loads against code. You create submittal packages, coordinate site access, arrange materials, and oversee install to fulfill schedule, budget, and warranty requirements without scope gaps.

Wrapping Up

You want a kitchen that works perfectly and complies with code on day one. With local expertise, a design-build approach, top-tier materials, and open scheduling, you'll get predictable results. Here's the proof: homeowners recoup an average 85% of a minor kitchen remodel's cost at resale (industry data), showing that function and finish pay dividends. Select a Muskegon team that captures specs, secures permits, and reports changes in writing—so your schedule, budget, and craftsmanship endure daily use and inspection.